Capabilities

Complete engineering services. CNC Milling - including Multi-pallet 5 Axis, Advanced CNC Turning with Twin Spindle and Power Tooling, Large Part Machining, 3D Scanning, 3D Printing, CAD / CAM, Laser Etching, Prototyping, Concept Design, Batch Manufacturing and full Supply Chain Support.

Development

A rapid, no nonsense approach to product development, overcoming complex technical challenges, finding solutions, building close working relationships and continually delivering to the highest standards. Pushing the boundaries of design and innovation. We get the job done!

Precision

World-class precision engineering, with a wealth of experience in Automotive, Aerospace, Defence and Motorsport applications, where failure is not an option. Complex, intricate components, precise inspections, 3D measurements and quality control, delivered 1st time, every time.

Introducing MAD

Design | Develop | Manufacture

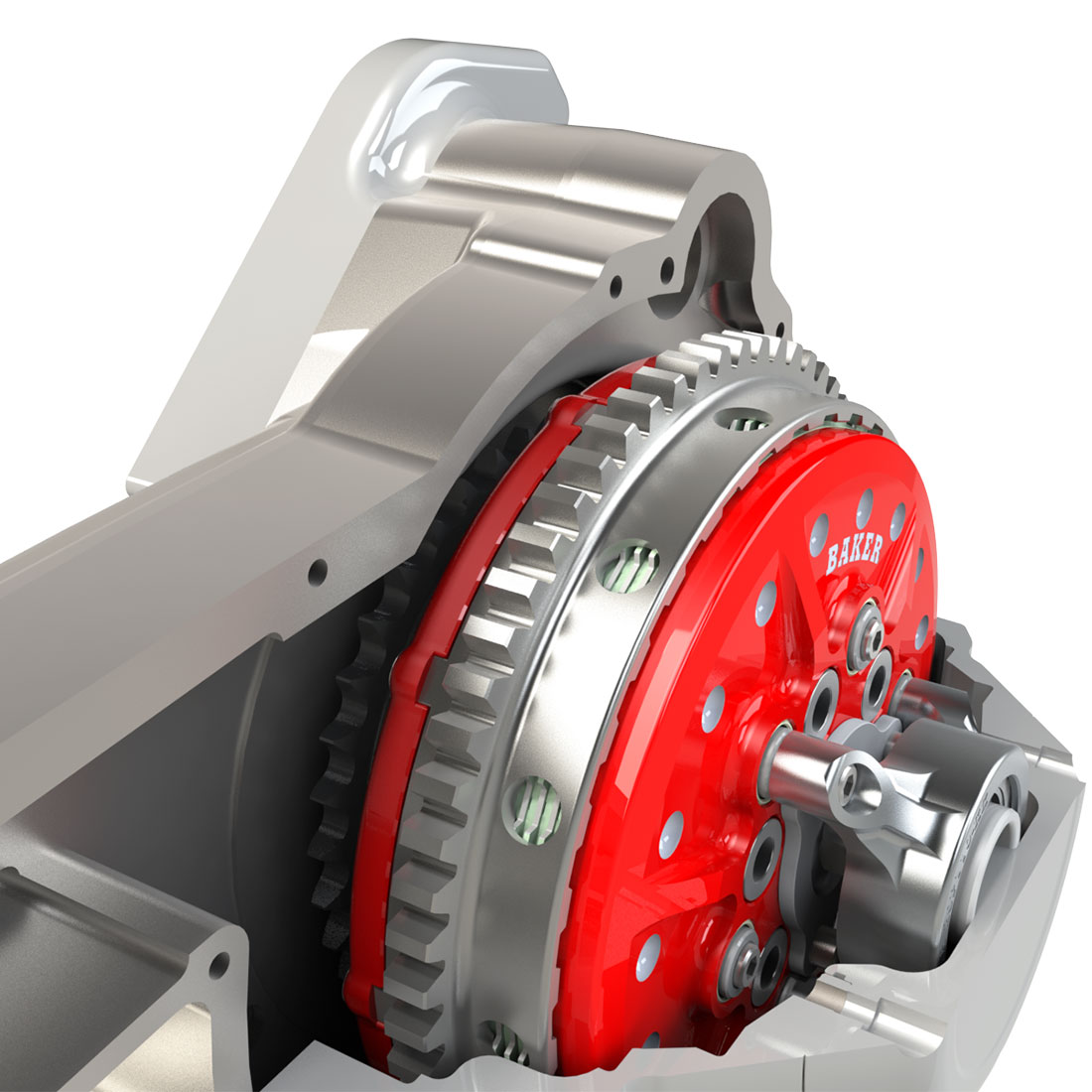

M.A.D. (Motor Sport Advanced Developments) is a world class precision engineering company located in Lancashire, UK. A name you can trust when it comes to producing the highest quality, precision engineering components, CNC machined products and CAD/CAM design/drawing capabilities to the highest standards. Working closely with our in-house technicians and customers, M.A.D has come to understand the engineering requirements of each of our clients, even helping to shape their ideas to create their ideal parts.

Our services

At M.A.D. we offer a complete engineering service that includes, CAD/CAM designs, prototyping and high volume production, then delivery of fully finished precision engineered components. Our well-equiped CNC machine shop houses a comprehensive range of machining, milling and turning equipment, all using CNC technology, that enables us to meet the exacting demands of our customers.

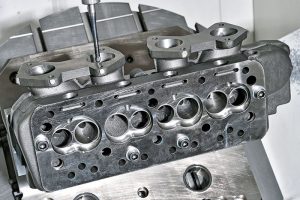

Precision

CNC Milling

World-class CNC Milling services including Multi-pallet 5 Axis, 5 Axis, 4 Axis and 3 Axis capabilities, geared for producing complex engineered components at the right price. Highly scaleable capacity, from prototyping to large volume, our capabilities makes the process of getting your CNC machined parts, simple. Start your CNC Milling project today, take advantage of our expertise and our experienced engineers will manage the complete process for you.

Advanced

CNC Turning

High quality, fast and efficient CNC Turning Services, from bespoke, complex turned parts to high volume mass production, MAD has the capability. Using state-of-the-art multi-axis CNC Lathes with twin spindle and power tooling, our experienced engineers can produce Turned and Milled parts that require slots, holes and grooves, all in one process. Contact us today, tell us what you need and our Turning professionals will manage the whole process.

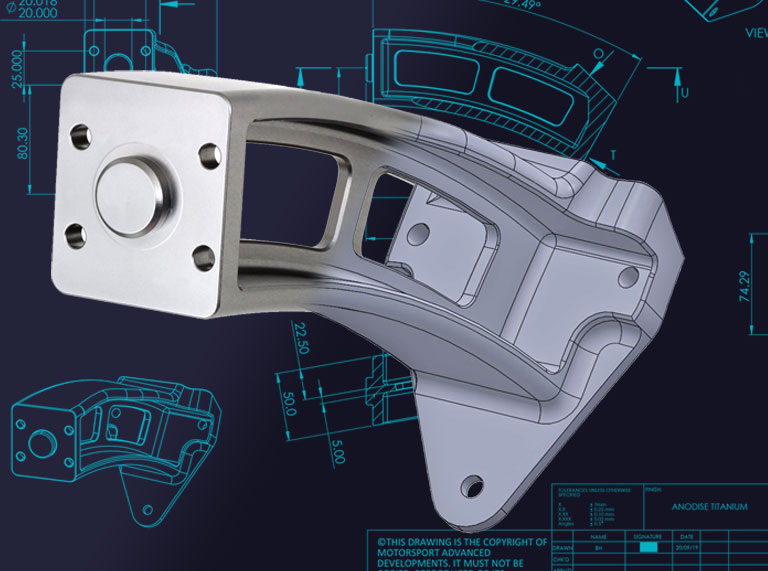

CAD CAM

Design

Our professional 3D CAD technicians, designers and engineers, can visualise your ideas, prove the concept and highlight potential issues before machining. Working with high end 3D software including Solidworks, Hypermill, Mazacam, plus the latest in 3D Scanning and Printing equipment our CAD CAM experts are here to help. Whether you’re innovating the next-generation aircraft, or simply need a component design bringing to life, get in touch today.

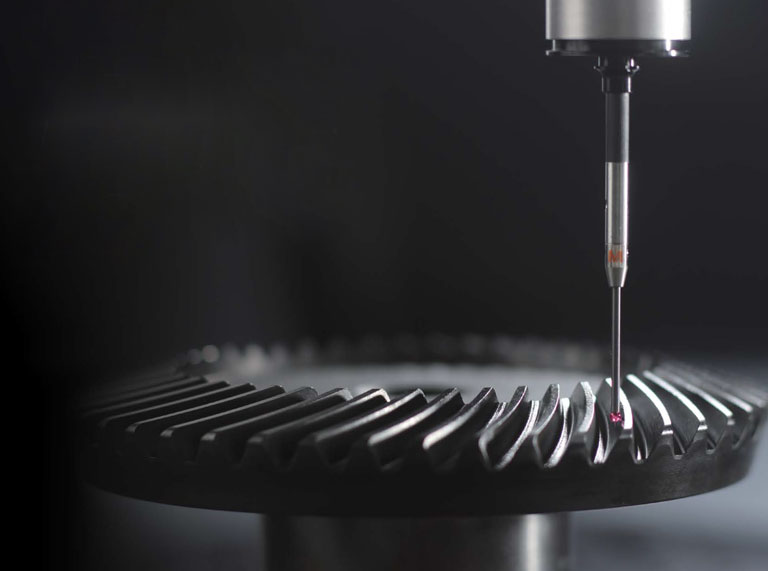

CMM Inspection

Ensuring precision of all components, measuring for accuracy and checking the quality is the critical factor in every manufactured part. The latest generation of Coordinate Measuring Machines, packed with state-of-the-art technology, enables us to perform efficient, high-accuracy measurements across a wide variety of components. Including products for the aerospace, automotive, medical, food and beverage, motorsport, petrochemical and military sectors.

Mazak Exclusive

CNC Machine Centers

Trusted around the globe, across all manufacturing sectors from F1 to Aerospace, Mazak machines lead the way. Through Mazak, MAD offers high levels of productivity, reduced production lead times, improved machining accuracy and lower operating expenses.

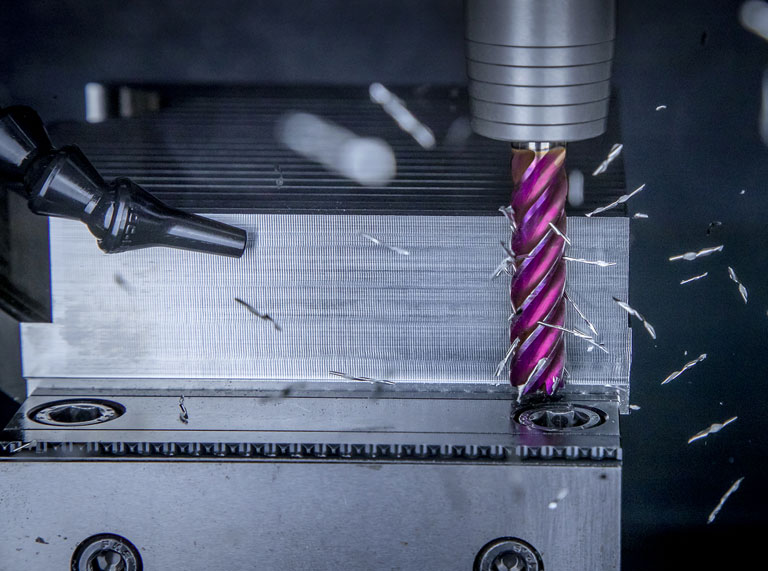

Ceratizit - WNT

Team Cutting Tools

Building a close working partnership with WNT over many years, has enabled MAD to tailor the right solution for every application. Our engineers have direct contact with the experts at WNT, giving us the ability to develop solutions along with analysing and optimising existing processes.